Polishing paste is used for polishing stainless steel, non-ferrous and precious metallic, wooden, plastic, ceramic, painted surfaces, etc. It is applied on the felt polishing tool or directly on the processed surface. It is used for machines, grinders, angle grinders without rpm adjustment and manual processing.

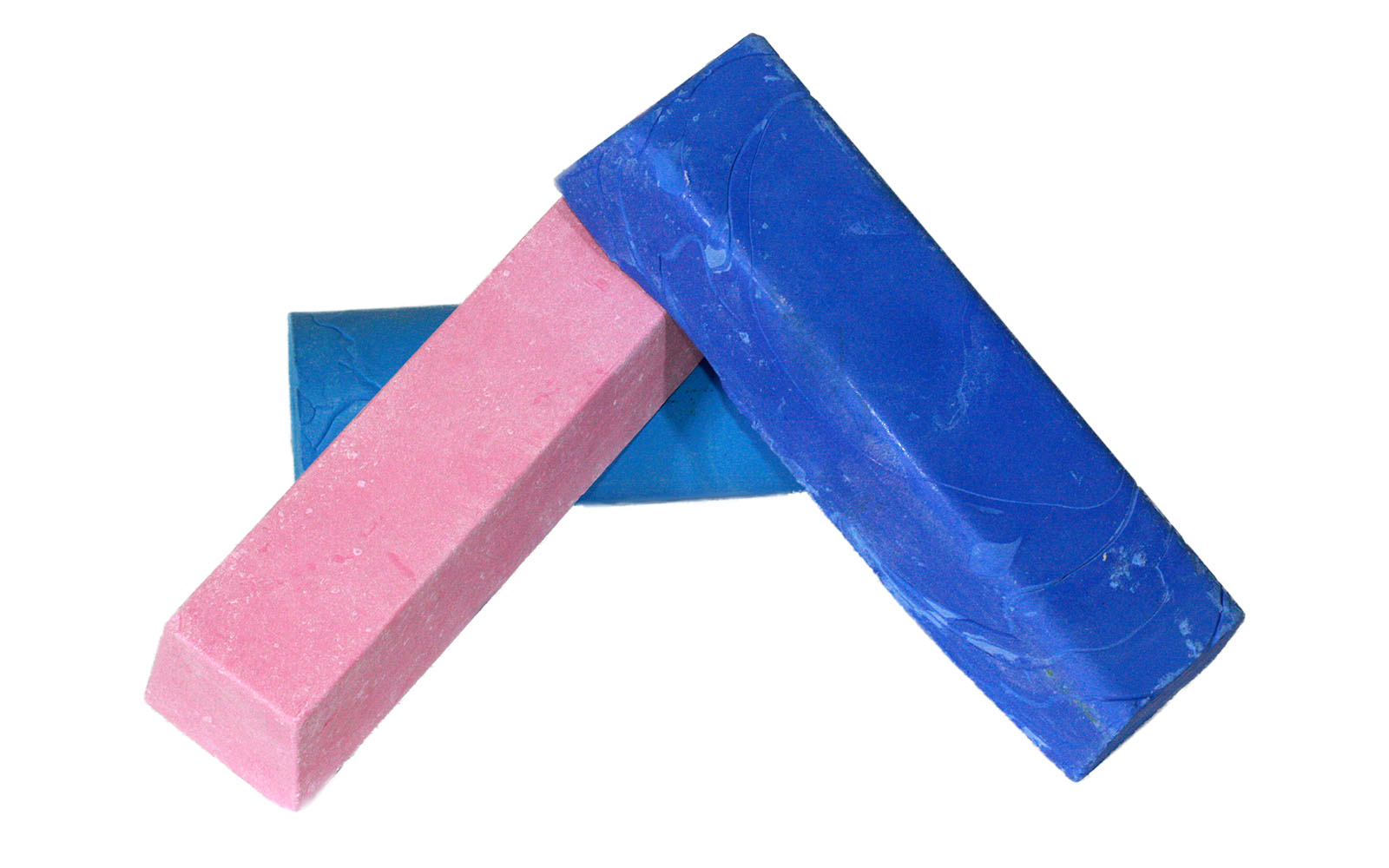

Our company specializes in professional surface treatment technologies and produces polishing pastes designed to achieve the demanded consumer qualities of the processed materials. We have developed three types of pastes for preliminary, final (universal) polishing and mirror-polishing. These pastes are painted in different colors to be easily distinguished.

Polishing pastes produced by InMake LLC are used at large manufacturing plants and small craft workshops for various types of work related to product processing.

The PN paste contains a complex of specially developed additives allowing a product to be cleaned faster, and hold abrasive powder on the tool that, in its turn, reduces the paste consumption. The paste is held on the tool even at high speeds when using an angle grinder together with our polishing tools:

Our pastes provide high productivity due to the content of high-quality abrasive powder — green silicon carbide 64C. In comparison with analogues, for example, aluminium oxide pastes, silicon carbide crystals are not smoothed or erased. This eliminates the material sticking and reduces the polishing time.

Important! Felt, foam, or other material is not a material that provides polishing when grinding. The paste itself provides polishing and the tool material is responsible for the correct distribution of the paste and holds it on the surface. The worse the quality of the polishing wheel is, the faster the wheel wears out and the paste consumption becomes higher as abrasive particles cannot be held on the surface. We recommend to use our felt polishing buffing wheels or other high-quality polishing tools with a felt density of at least 0.5 g/cm3.

Important! The temperature of the treated surface should not exceed 120°C as overheating leads to evaporation of the paste components.

Product range

| Item number | Colour | Application field |

|---|---|---|

| PN-1 | Dark blue | Pre-treatment. Polishing of ground steel, non-ferrous metals, marble and plastic. |

| PN-2 | Blue | Final polishing. Universal paste for polishing stainless steel, acid-resistant metals (aluminum, copper, silver, nickel), and their alloys. |

| PN-3 | Grey | Mirror-polishing treatment. Dry paste, designed for very fine buffing and making the surface to have a mirror shine. It is used for decorative buffing of gold, chrome, nickel and stainless steel. |